HOLLOW INJECTION (DSI technology)

DSI (Die Slide Injection Molding) is a type of injection mono material that enables faster molding, more accurate complicated structures, including troughs, developed by JSW. DSI uses two injection process: first, the intermediate molding shells (divided in two), a displacement of the mold cavities then to repositionning the shells facing each other. The second material injection is used to fuse the shells. Injection of conventional hollow structure keeps heterogeneous thickness and more reliable melting connections. DSI technology addresses these issues perfectly

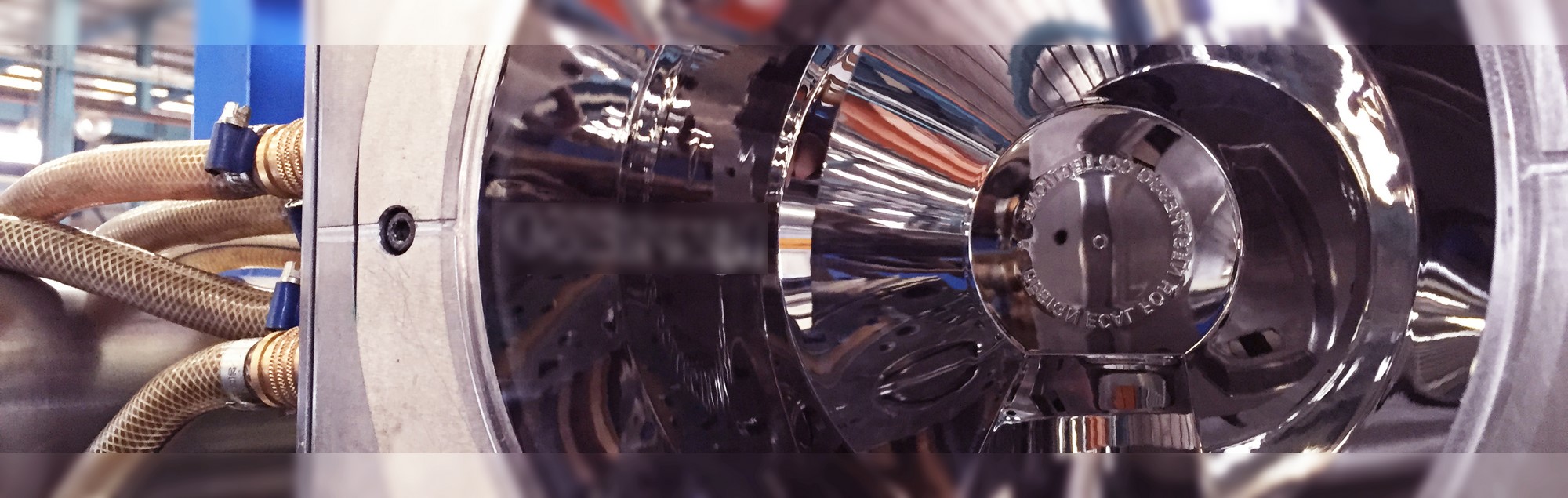

IMPEC MOLD was the first in France to produce tools for the hollow injection (DSI technology) on an injection molding machine with single material.

Advantages:

- The Dsi technology provides flexibility in the assembly process of complex parts

- Faster, because all pass during injection parts, for an economic gain

- Removing insert or components within the product before welding.

- No Operation post molding assembly as ultrasonic welding, screws, or adhesive bonding.

- Allows the welding parts in 3D parting